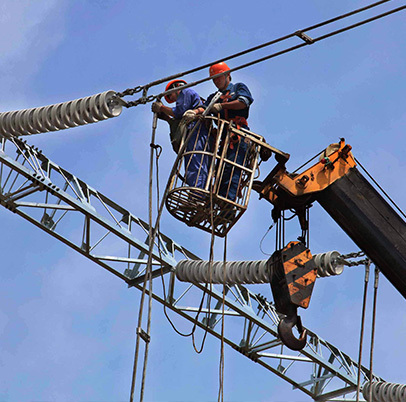

Importance of End Connection of Composite Insulator

Release time:

2019-06-25

Sealing at the junction between the end fittings of synthetic insulators and the sheath of the mandrel has not received sufficient attention, which may be the cause of brittle fracture of the mandrel and interface breakdown. Most of the end connection structure of silicone rubber insulator is wedge-connected, and slippage between the core rod and the hardware is inevitable in long-term heavy load operation. When the sealant and metal bonding force is poor, the small slip is enough to make the seal seam; when the sealant elasticity is not enough, the excessive slip can make the sealant broken. From this point of view, the use of crimping end structure is one of the ways to prevent seal damage. In addition, the engineering application sealant is mostly room temperature silicone rubber, its anti-aging performance is obviously not as good as high temperature silicone rubber, in the case of corona in the end fittings may lead to premature deterioration. For products of 110 kV and below, there is a greater risk of not using the pressure equating ring, or the position of the pressure equating ring of 220 kV and the upper product is not installed properly. In short, whether the end seal is maintained for a long time under long-term electromechanical action still needs to be tested and demonstrated and tested for long-term operation.

Sealing at the junction between the end fittings of synthetic insulators and the sheath of the mandrel has not received sufficient attention, which may be the cause of brittle fracture of the mandrel and interface breakdown. Most of the end connection structure of silicone rubber insulator is wedge-connected, and slippage between the core rod and the hardware is inevitable in long-term heavy load operation. When the sealant and metal bonding force is poor, the small slip is enough to make the seal seam; when the sealant elasticity is not enough, the excessive slip can make the sealant broken. From this point of view, the use of crimping end structure is one of the ways to prevent seal damage. In addition, the engineering application sealant is mostly room temperature silicone rubber, its anti-aging performance is obviously not as good as high temperature silicone rubber, in the case of corona in the end fittings may lead to premature deterioration. For products of 110 kV and below, there is a greater risk of not using the pressure equating ring, or the position of the pressure equating ring of 220 kV and the upper product is not installed properly. In short, whether the end seal is maintained for a long time under long-term electromechanical action still needs to be tested and demonstrated and tested for long-term operation.

Previous article

Previous article

Related News